electric up to 6mm thickness manual plate rolling bending machine

Product Description

Products Description

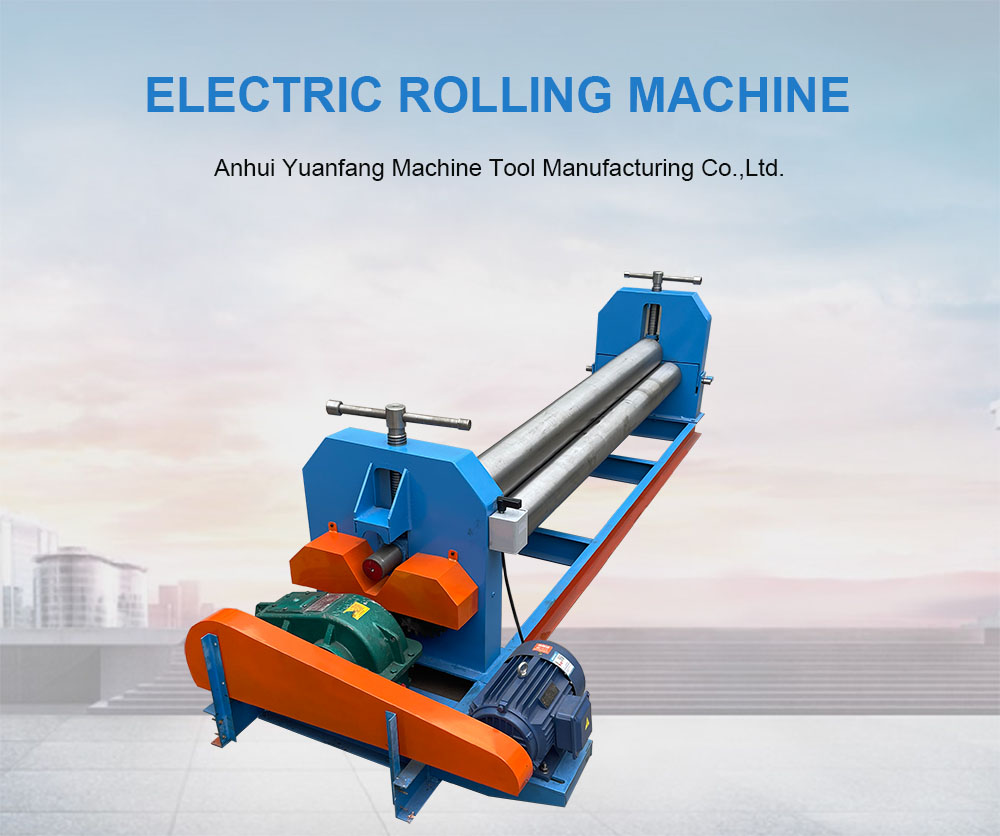

Electric Mechanical Plate Rolling machine

The use of the overall frame welding and annealing treatment; Three-roller symmetric structure; driven by screw lever and turbine worm, the upper roller moves in vertical direction in the center symmetrical position between the lower two rollers; As the main drive roller for rotary motion, two lower rollers are engaged with the output gear of the reducer to provide torque for rolling plate. The machine is compact, easy operation and maintenance; besides, the roller is suitable for installation of profile dies for easy rolling of various profiles. Easy-to-use removable console. Two sets of digital output for easy positioning of two lower rollers. Upper roller lifting motion principle: auxiliary MOTOR and auxiliary reducer drive the worm and turbine under lateral bearing seats to move, consequently rotate the screw nut on the turbine to lift screw lever. Unloading device: when finishing rolling work, the upper roller rises up, the pull rod on the end of upper roller holding the roller, then disconnects the left bearing seat namely tiltable bearing seat and extracts the pin shaft, turnover the tiltable bearing seat, finally, the finished ferrule will be released from the other end of the upper roller.

Details Images

Roller

■ Forged material for the Solid Roller

■ Hardened treatment for whole roller

■ good wear resistance, long working life,

Main Drive and rolling

■ High quality,all copper core,main motor is changed by reducer, the working roller is driven by the gear.

■reverse switch is convenient for rolling plate operation.

Product Paramenters

Technical parameter

Related Products

Company Profile

Our service

Pre-service: |

1.We will help you confirm the model of our machine according to the working capacity |

2.Very welcome to see our product how to work in the factory before you place an order with us. |

3. Provide sample and design plan for some product. |

Aftersales-service: |

1.Free installation, trial start and adjustment, training. |

2.You can come to YOUTRUE factory for training. We will offer professional guide. Direct and effective face-to-face training. |

3.Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service. |

Packing and shipping

Packing up to shipping standard

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of themachine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

FAQ

1.Can you supply the relevant documentation? Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required. 2.What is the average lead time? For samples, the lead time is about 10 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so. 3.What kinds of payment methods do you accept? You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L. 4.What is the product warranty? We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction. 5.Do you guarantee safe and secure delivery of products? Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge. 6.How about the shipping fees? The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Product Categories : Rolling machine

Premium Related Products

Other Products

Hot Products

New Product for Sale CNC Hydraulic Steel Shearing MachineChina Factory Guillotine Hydraulic Shearing Machine1250 Tons H Frame Hydraulic Press for Automotive Parts 1250t H Type SMC Sheets and Moulding Hydraulic Press Machine1000 Tons H Frame Hydraulic Press for Automotive Parts 1000t H Type SMC Sheets and Moulding Hydraulic Press Machine3 Axis 63t/2500 CNC Press Brake with Delem Da52s CNC Press Brake 63 TonsManufactory Mvd 2015 New Product 60 Tons C Frame Hydraulic Press3 Axis CNC Press Brake 63t/2500 with Delem Da52s CNC Press Brake 63 Tons2500mm Hydraulic Cutting Machine 2mm Metal Cutting MachineHydraulic Press Brake 63 Tons Press Brake 63/2500mmManufactory Mvd 2015 New Product Hydraulic Metal Stamping Machine 60 Tons C Frame Hydraulic PressH Frame Hydraulic Deep Drawing Press MachineH-Frame SMC Hydraulic Press 1000 Tons SMC Manhole Cover Moulding Hydraulic Press for CE & SGSMvd Hydaulic Shearing Machine with CE & Nr12Hydraulic Press Brake Machine with CE & Nr12YAG Laser 500W Carbon Steel / Stainless Steel CNC Laser Cutting Machine3 Axis 30t/1600 CNC Press Brake with Delem Da52s CNC Press Brake 30 Tons